Insulation & Air Tightness

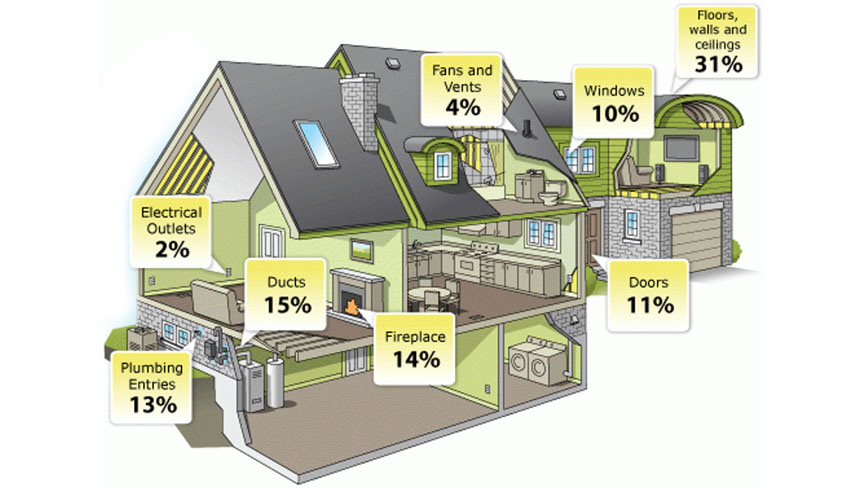

A well-insulated house is cheaper to heat than one with insufficient or inadequate insulation. If the warm air your heating system generates escapes through gaps in the insulation, or via thermal bridges or cold bypasses, the cost of heating the property will rise significantly, compared to the cost for a properly insulated home.

Air Tightness

How fast the warm air inside your home escapes depends on the airtightness of the building. The minimum standard required to pass Building Control regulations for air permeability is a maximum value of 8.0, which means that for every square metre of surface area, a maximum of 8 cubic metres per hour of warmed air can be lost through leaks in the building fabric. For a new Passivhaus, the rate of warm air lost per hour must be less than or equal to 0.6 cubic metres.

Design standard vs ‘as-built’

There is often a big difference between the design standard of 5m3 for air permeability and the ‘as built’ result, which is more likely to be closer to the maximum allowable 8.0m3. Paying attention to detail during the build and achieving air-tightness close to 5.0m3 will mean an airtight home which will result in a substantial saving on your annual heating costs, forever.

Insulate to prevent heat loss

Thermal bypass occurs when warm air travels through the insulation, rather than being retained inside the insulation. Warm air can only travel through insulation when there are gaps in it, so the quickest and easiest way to stop the passage of air is to fill every available square millimetre with heat trapping, breathable insulation.

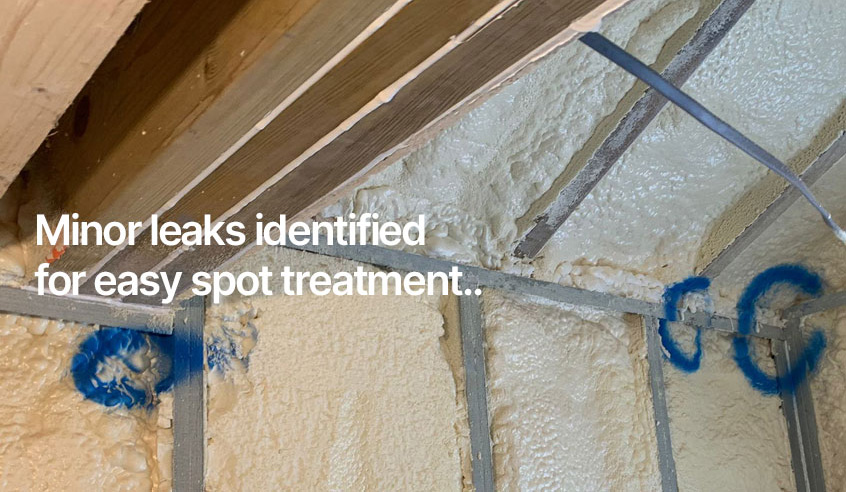

However, gaps in poorly fitted insulation will be covered up by the plasterboard unless checks for airtightness are made during the build, when leaks can be sealed and the house re-tested, so that the building is as air-tight as possible.

Expanding Spray Foam Insulation

The most commonly employed method to achieve airtightness is to fill gaps with wool or recycled newspapers, which can deteriorate over time, and then make an air-tight seal using material such as membrane and tape—which is labour intensive and costly. The most efficient method uses expanding spray foam insulation that provides a complete seal of every surface and an air barrier of the same thickness, which is an integral part of the insulation. Spray Foam insulation will not deteriorate or over time.

There are two types of expanding foam insulation, open cell and closed cell

Open cell

Open cell polyurethane foam is a lightweight, flexible and breathable type of polyurethane that’s applied directly onto timber frames or sarking boards as an insulation layer.

Open-cell spray foam expands to 100 times its original volume, filling every crack and crevice that might otherwise allow air to escape. Because it’s an excellent soundproofing material as well, open cell foam insulation is a great choice for homes near busy roads or airports.

Open cell spray foam insluation should not be used for steel, masonry, non-breathable underlay or flat roofs that lack insulation.

Open Cell spray foam insulation

Closed Cell

Closed-cell insulation is a spray-applied or cavity injected, rigid polyurethane foam. When applied it ‘sets’ just like rigid PUR board insulation – but the advantage is that closed cell can be sprayed much faster without leaving gaps and voids in the wall system.

Structural foam is used in steel and masonry insulation, forming a rigid filling between internal walls. It should not be used to fully encapsulate timber or as a substitute for tanking.

Contact us for further information regarding insulation for your project, or please have a look at the Solarcrest website